How To Build A Dry Sump Oil System

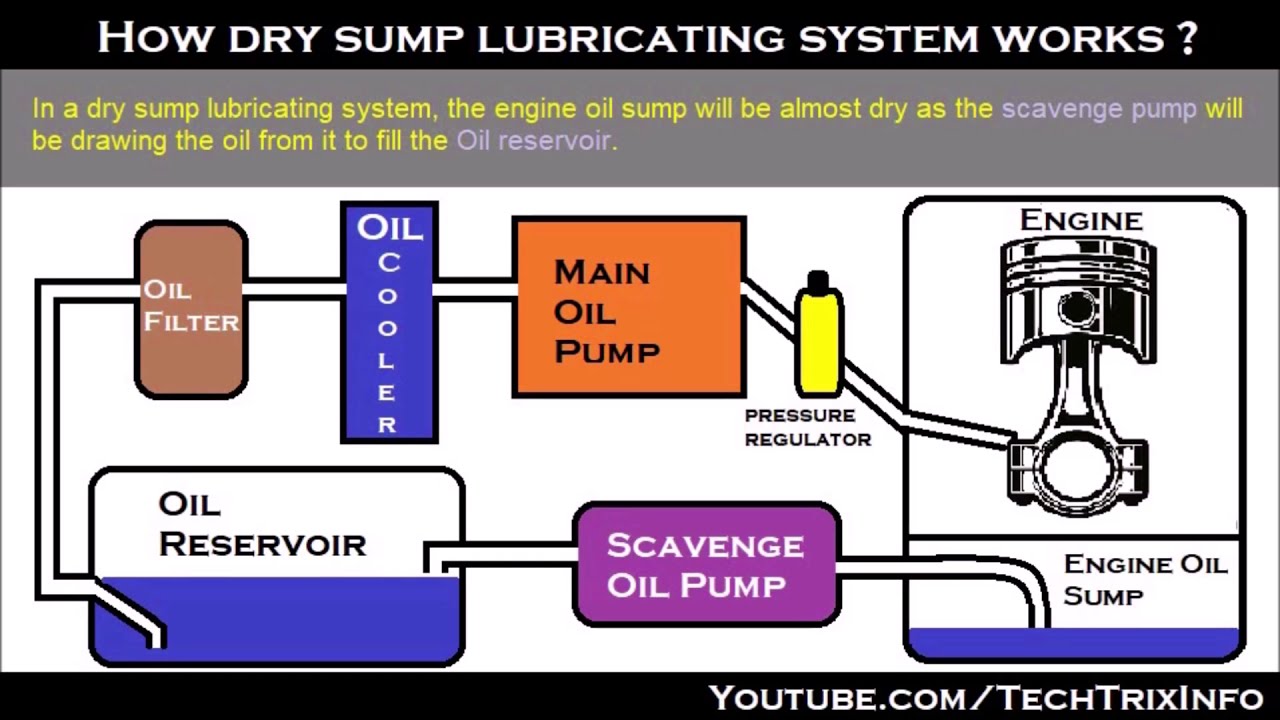

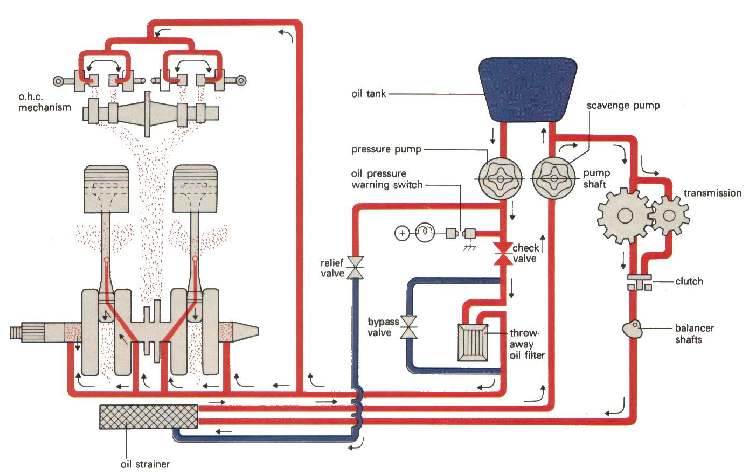

How to build a dry sump oil system. The main difference between the wet and dry sump systems is where the oil is stored. The oil reservoir has an oil pump on it that then pumps the oil back into the motor. Oil is pressurized and sent from the top of.

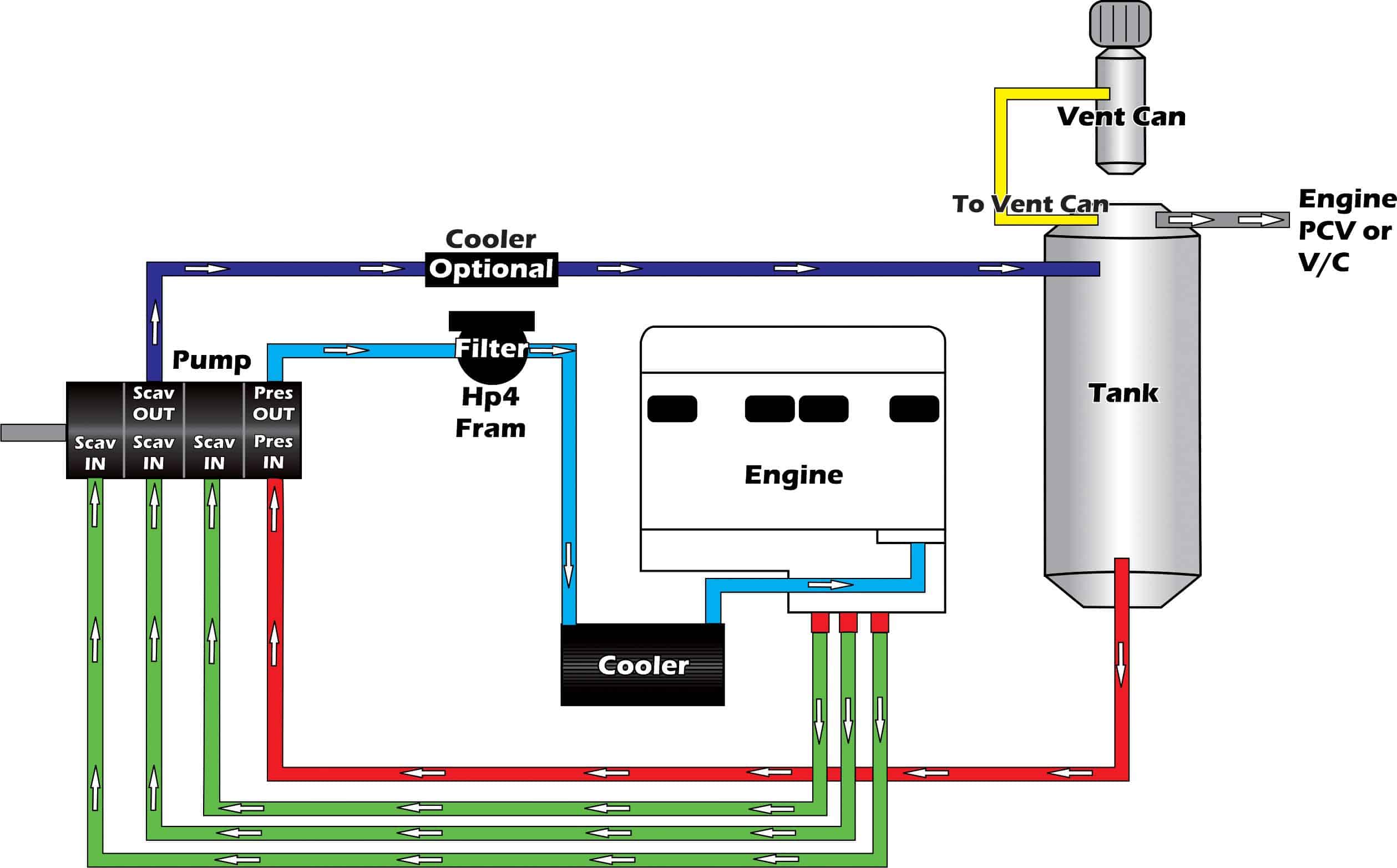

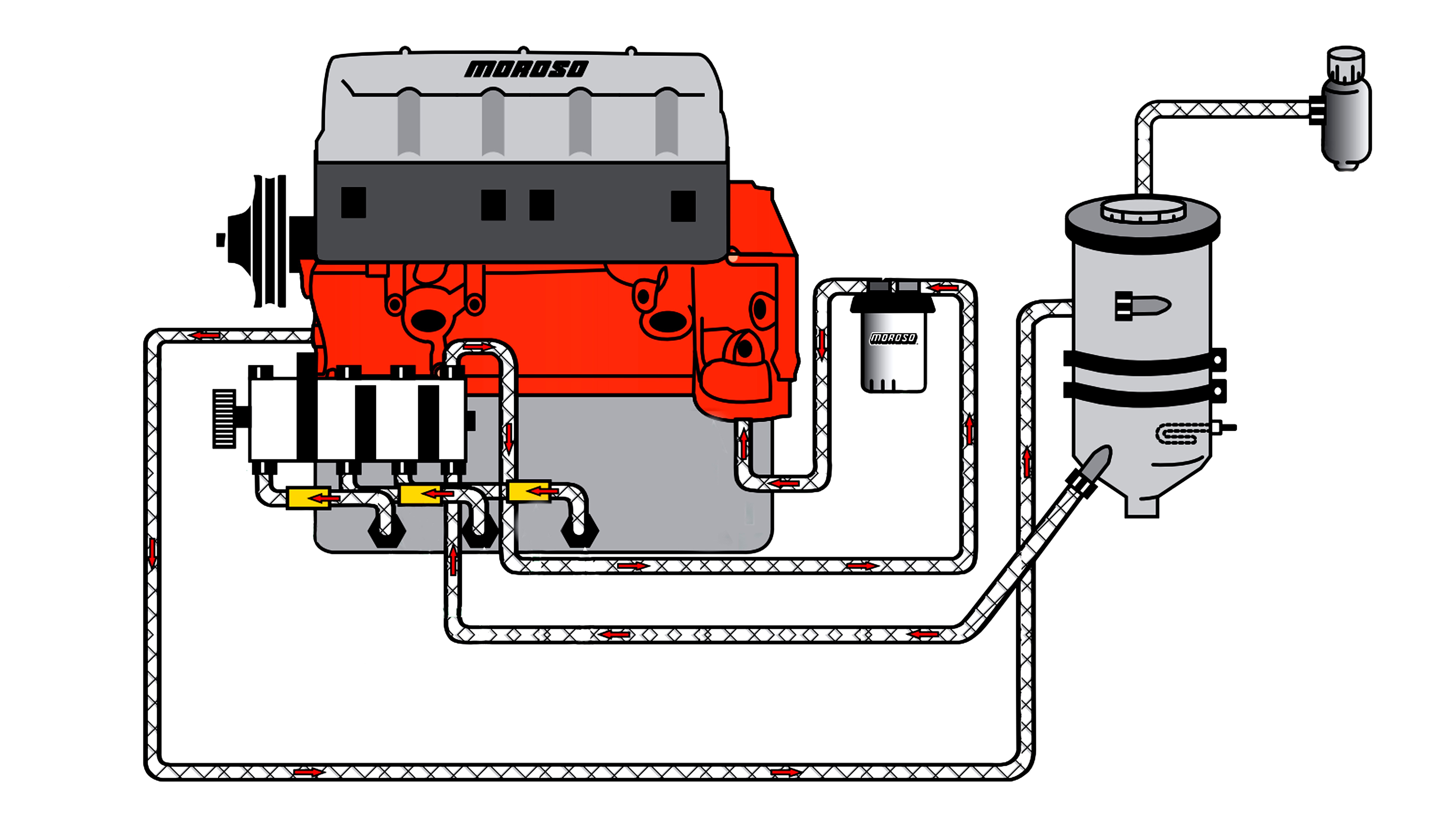

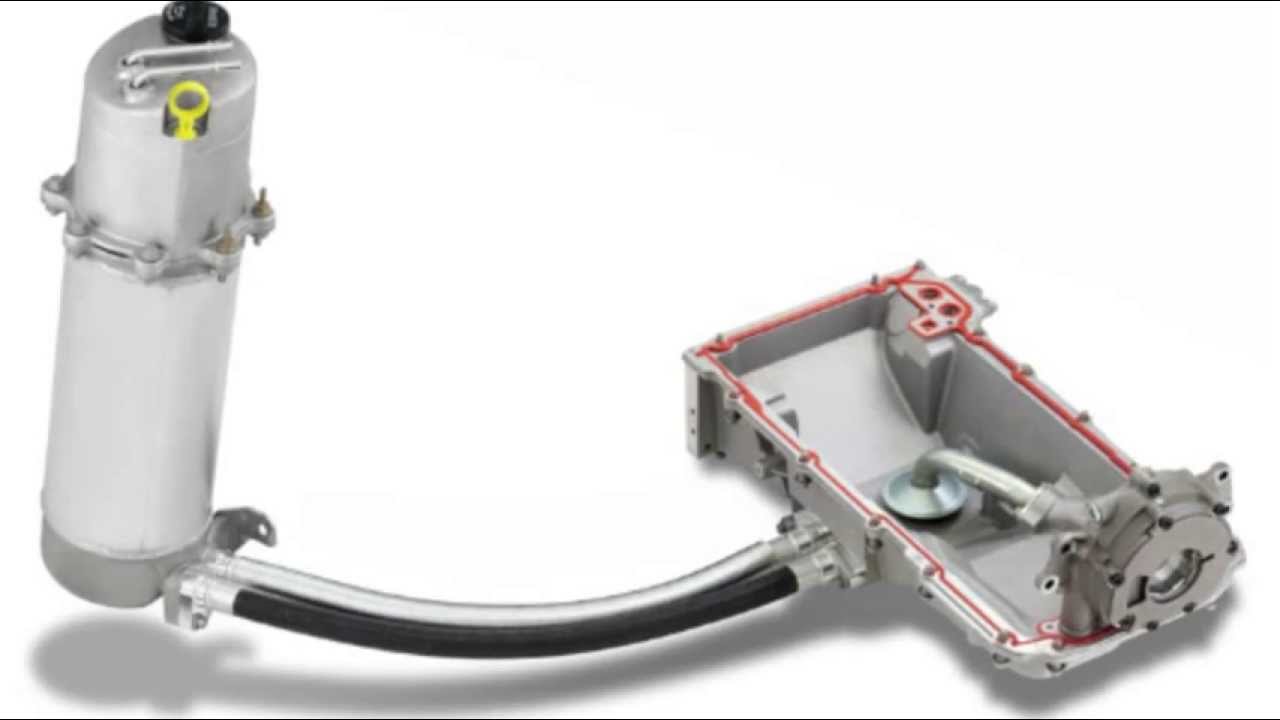

Dry sump oiling systems store their oil supply in a separate tank leaving the oil pan virtually dry because multiple scavenge pumps suck it out as fast as possible. Most dry sump engines should should have the oil level checked immediately after the engine has been run. Oil Tank design is one of the key components to an effective Dry Sump System.

Dry sump oiling systems are the safest most dependable oiling systems available and theyre popular. Oil is then returned to the top of the engine to carry out the same process again. The Primer Remote Filter Mount uses the same twisted four-lobe rotor thats in all of their oil pumps and can provide 20 psi of oil pressure in less than 10 seconds.

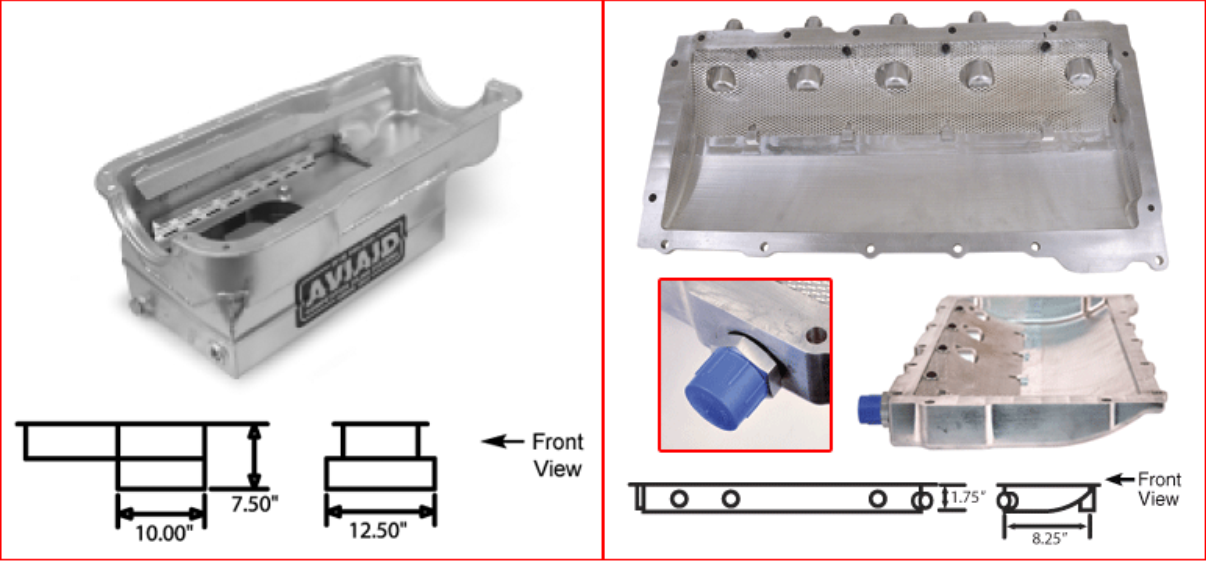

Because the bulk of the engine oil is no longer being stored in the sump of the oil pan the pan can be very shallow allowing our engine to sit 125 inches lower. Instead the oil is sucked out of the motor by an oil pump in one or several locations. It is the outside one of the two oil drain plugs.

Yes dry sumps are nice and would be best for long term but designing a system on the go is difficult. Although of less importance in a straight-line drag racing application dry sumps are less susceptible to oil pressure loss in racing environments where high-g loads from high speed cornering slosh the oil out of reach of the pickup tube. Wet Sumps and Dry Sump Oiling Systems.

Now mine of course is attached to the bottom of the radiator Ive yet to see another car like this so your build may differ although Caterham tell me my car is the new 420 design so builds from 2019 onwards should be applicable. It keep the motor in oil during the time the pump cavatates and refills when on the straights. A dry sump oil system is different in that it doesnt have an oil reservoir in the oil pan under the motor.

Enhance safety by minimizing oil volume inside the engine. When they sit for awhile oil may seep under gravity into the dry sump and give a false low reading at the oil tank.

Dry sump oiling systems are the safest most dependable oiling systems available and theyre popular.

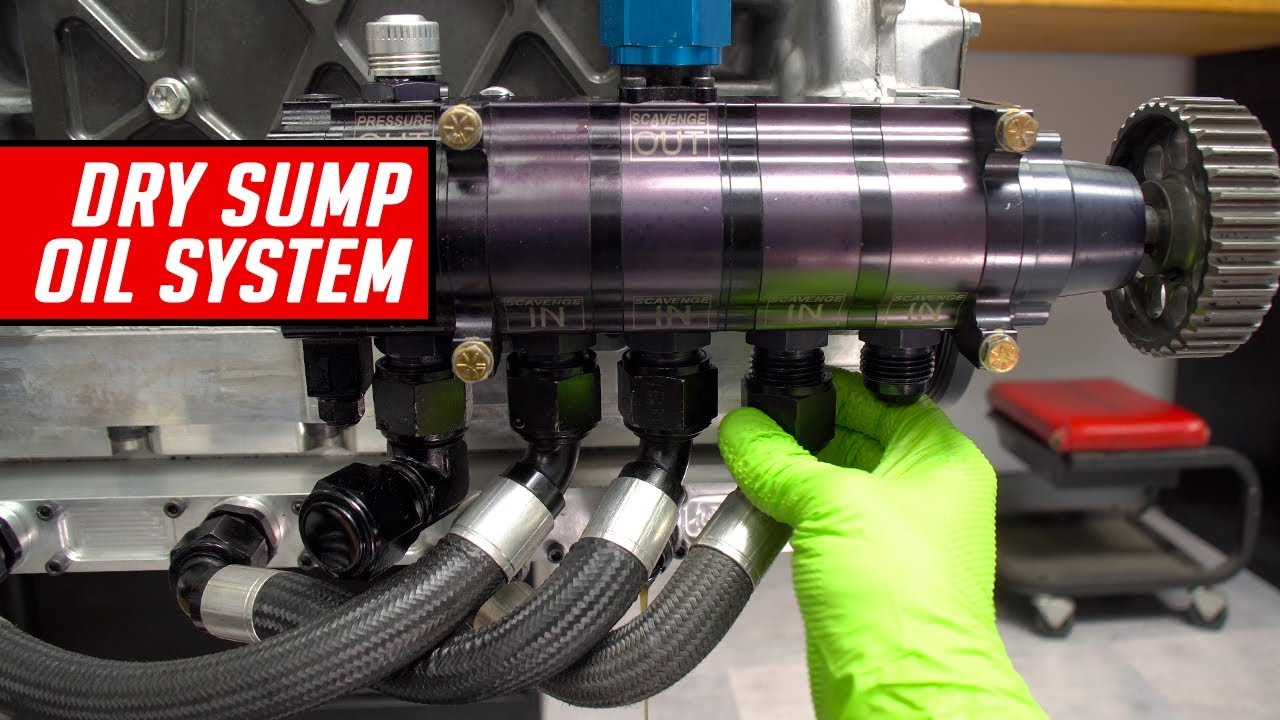

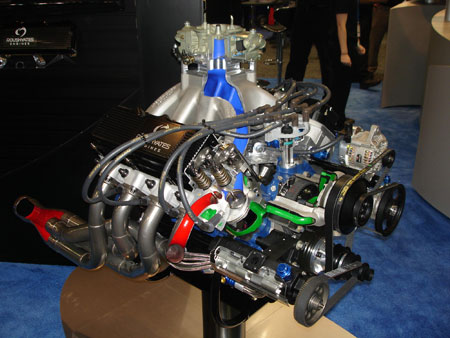

At this point you will need an oil cooler in place. At this point you will need an oil cooler in place. Oil is pressurized and sent from the top of. A dry-sump oiling system consists of the dry-sump pump itself which can have anywhere between one to six stages. Find How To Build A Dry Sump Oil System Manufacturers Suppliers from China. Each unit is made of billet aluminum and can be rebuilt at home with an O-ring kit and some seals available through Peterson when its time to perform service. The improvement in the quality of the oil that reaches the bearings with a dry-sump system is usually apparent when you overhaul the engine. Yet dry sump oil systems free up horsepower and keep engines alive through grueling conditions better than a standard wet sump setup. S cavenge stages built into the oil pump evacuate oil from the pan and create a vacuum in.

A dry-sump oiling system consists of the dry-sump pump itself which can have anywhere between one to six stages. The drain plug for the dry sump taps into this passage. The Primer Remote Filter Mount uses the same twisted four-lobe rotor thats in all of their oil pumps and can provide 20 psi of oil pressure in less than 10 seconds. Oil Tank design is one of the key components to an effective Dry Sump System. To show how this seemingly magic setup works Papadakis Racing created a video to show the ins and outs of a dry sump system. The oil reservoir has an oil pump on it that then pumps the oil back into the motor. Wet Sumps and Dry Sump Oiling Systems.

Post a Comment for "How To Build A Dry Sump Oil System"